304-E

High Surface Quality Guaranteed after Deep Drawing

High Elongation and Deep Drawability

For Cylindrical Deep Drawing Only

It should be preferred for deep drawing of cylindrical products requiring high elongation.

It aims to achieve maximum elongation in one go and a surface without orange peel effect in deep drawing operations such as cookware.

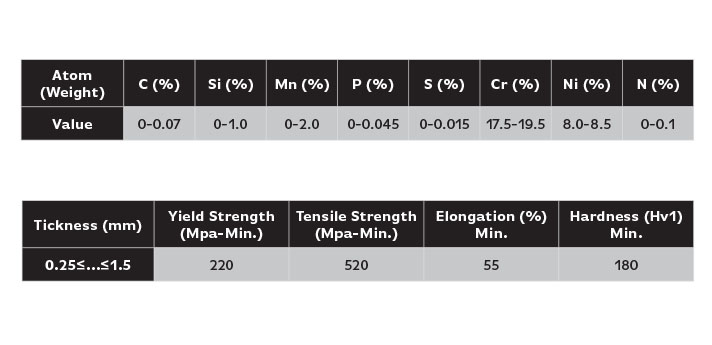

304E Mechanical and Chemical Properties

304-U

Guarantees Homogeneous and Maximum Deep Drawing Ratio in One Pass

It should be preferred for the deep drawing process of angular complex products requiring high elongation.

It aims to achieve maximum elongation in one pass in complex deep drawing operations such as kitchen sinks.

304U Mechanical and Chemical Properties

Smart Heat Treatment

What is the difference from other DDQs?

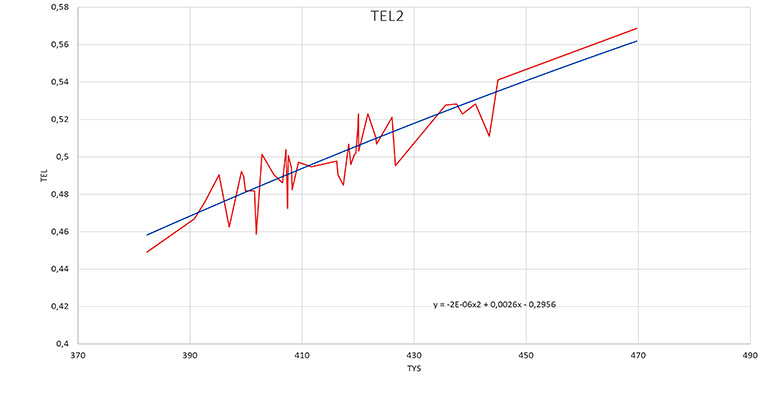

Comparison with other DDQs

304 DDQ

• High Nickel Content

• Deep Drawing Capabilityi

• High Corrosion Resistance

• Wide Mechanical Ranges

• MMin 55% Elongation

304-E DDQ

• Normal Nickel Content

• Harder, Hardness Min. 180 HV1

• Extra High Deep Drawing Ability

• High Corrosion Resistance

• High Surface Quality After Deep Drawing

• Surface with Low Orange Pattern (Sandblasting) Effect

• Specific Mechanical Properties

• Min 55% Elongation

304-U DDQ

• Normal Nickel Content

• Soft, Hardness Max 180 HV1

• Ultra High Deep Drawing Capability

• High Corrosion Resistance

• More Deep Drawability in One Pas

• Specific Mechanical Properties